How to Install a Telescopic Sliding Gate

Telescopic sliding gates are used when there isn't enough room for a single piece sliding gate to open because they require only half the space.

READ MORE about Telescopic Gates

When Installing an Automatic Gate that will be entered from a public road way, make sure the Gate is placed far enough from the road to prevent traffic congestion and is installed in a location that provides adequate clearance between it and adjacent structures when opening and closing to reduce risk of entrapment.

The Gate and Gate Operator must comply with any applicable local council regulations.

Installing the Footing for a Sliding Gate allowing for a Motor

If you have a concrete driveway or paver's glued to a concrete base then the footing for your sliding gate is halfway there. If you have a bitumen or gravel driveway you will need to dig a channel across the driveway and install concrete ...

READ MORE about Installing Footings for Telescopic Gates

Installing Posts for Sliding Gates

Metal posts are best because they don't warp or twist with changes in weather conditions. Posts for sliding gates don't need to be as large as those for swing gates ...

READ MORE about Installing Posts for Automatic Gates

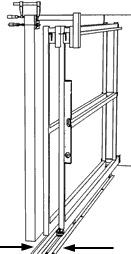

Installing the gate

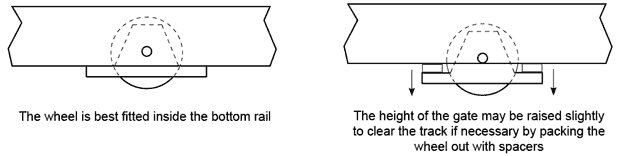

Fit the wheels to both gate panels first using Tek screws. This makes it easier to move them around with scratching them.

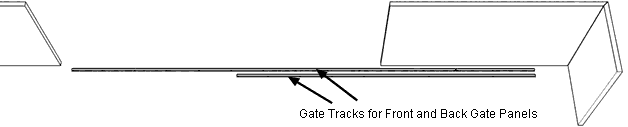

Lay the tracks down where the gate is to be installed but don't fix it in place yet.

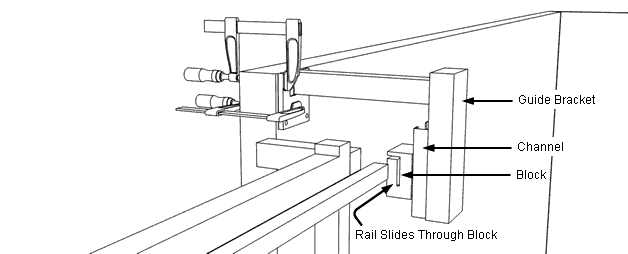

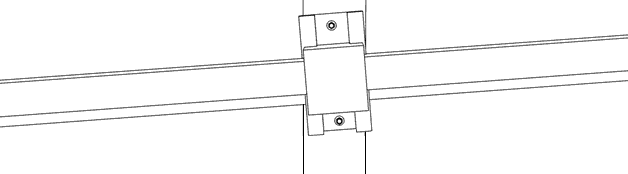

If using a 'U' bracket, block and rail use 'F' Clamps to clamp the bracket to the gate post or wall other wise if you haven't already install the guide post. Place both gate panels on their tracks and fit the guide blocks so you can test whether the gate opens and closes properly without rubbing on the track.

If the gate does rub on the track you can pack the wheel out a bit so the gate sits a little higher and stop this happening. You may need longer Tek screws to refit the wheel.

Checking Clearances

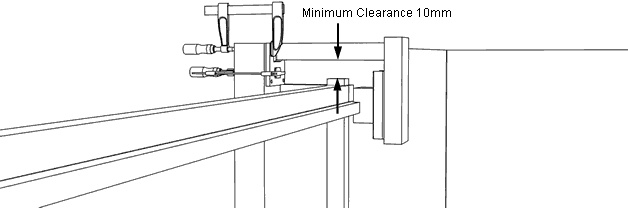

If using a guide bracket check also that the gate has at least 10mm (3/8") clearance between the top of the gate and guide bracket for the entire length of the gate. If the driveway has slope across it (camber) then this will be at the highest point.

If the driveway has slope across it and the top rail of the gate is at an angle the guide block will need to be fitted on an angle too so the guide rail doesn't grab in the block. If the gate is stiff to push in one direction but not the other then the angle isn't quite correct. If you use one Tek screw to start with then you can clamp the channel for the block at different angles until you find the angle that runs the smoothest.

Clamp the Keeper where you think it should be then close the gate and if using a guide rail make sure it clears the keeper by at least 10mm otherwise move it down.

You can now fit the Keeper and guide bracket if used permanently using suitable hardware. It is vital that the guide bracket cannot come loose for safety reasons because if it does the gate could fall over and injure someone, which is something we all want to avoid.

Fitting the Track

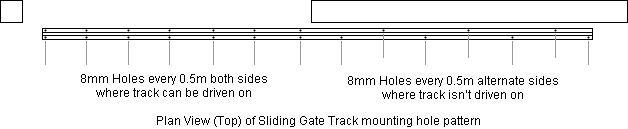

Now remove the gate so you can install the track permanently. Mark out and drill mounting holes in the track as follows:

Where you drive over the track on the driveway you should drill an 8mm (5/16") hole every 500mm (20") on both sides of the track. Where the track goes behind the fence you'll only need a hole every 500mm (20") on alternate sides as this doesn't need nearly as much strength.

Before fixing the track in place put the gate back on the track again and check that the gate is plumb and that it lines up with the posts and keeper.

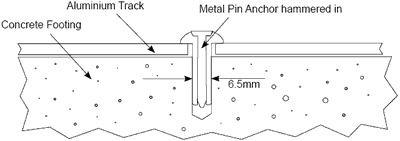

To fit the track use metal pin anchors, which are available at most nut and bolt suppliers as these are quick to fit, look nice and hold better than Dynabolts.

You need to drill holes in the concrete the correct size for the pin anchor, the 6.5mm (1/4") anchor is the most suitable requiring a 6.5mm (1/4") hole.

Pin the ends first and check the gate is lined up from fully closed to open, then install the remainder of the pin anchors.

Hard Stops

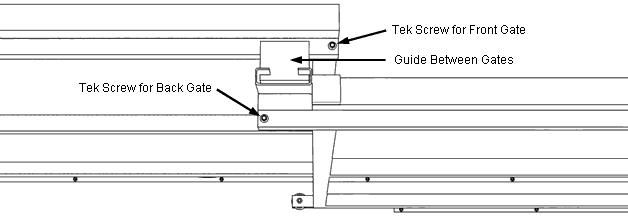

To prevent each gate panels sliding off their guides and falling over fit Tek screws on the guide rails as follows:

If you are fitting timber palings, hardwood slats, metal slats or metal sheet to your gate now is a good time to do it while you can still move each panel individually.

Fitting the Wire Rope

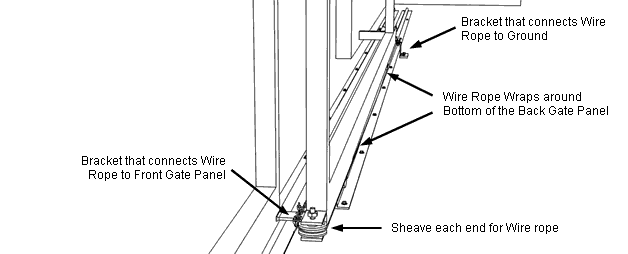

Now its time to fit the wire rope that connects the two gates together so moving the back gate will move the front gate with it.

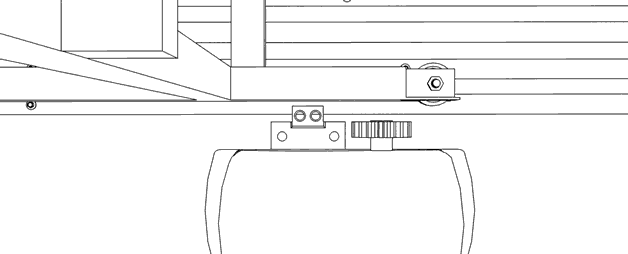

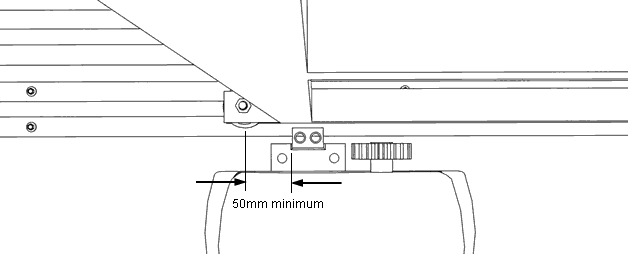

Placement of the bracket that connects the wire rope to the ground is critical so it doesn't interfere with the motor. If you place the motor where it should go according to its installation instructions but don't fix it in place yet, you should now determine where the ground bracket should go.

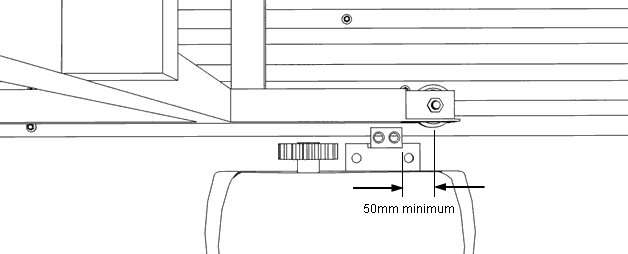

The ground bracket should go as close to the motors output gear as possible. It can go either side depending on where the output gear is positioned on the operator. Each sheave should be at least 50mm (2") from the ground bracket when the gate is opened or closed.

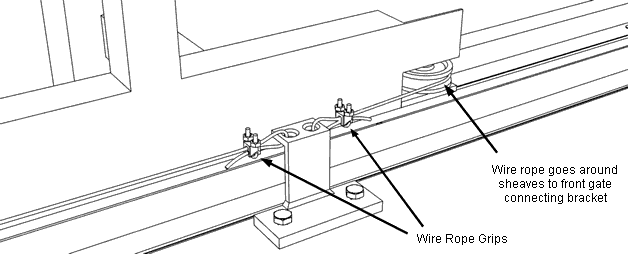

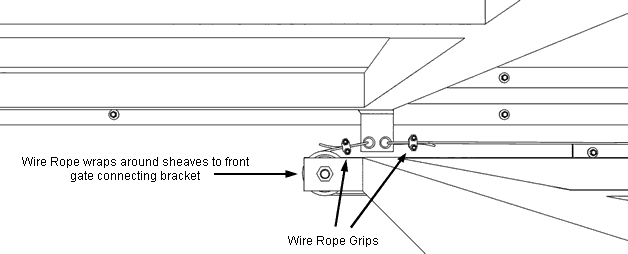

The Ground Bracket should be Dyna bolted to the ground firmly so it can't be pulled off. Then with the gate fully closed the wire rope can be fitted around the sheaves to the front gate connecting bracket, making sure the rope is tight enough so it doesn't sag on the ground.

Now when you push the back gate panel the front gate panel will move at twice the speed.

You are now ready to fit a standard sliding gate motor.